|

|

Silicon Steel CNC Automatic Transformer Core Lamination Servo Motor Cut To Length LineThe core of transformer is the heart of transformer. HJ series core cutting machine is specialized equipment for production of transformer cores; It process the lamination of yoke, leg, center leg and etc. The equipment adopts the automatic control system, operation easily, high automation and precision. Its manufacturing quality directly affects the performance and operation of transformer. The processing technology of the core, the composition of the production of the core cutting line, the operation method, the precision adjustment, the flatness of the silicon steel sheet, the shearing precision, the burr tolerance and so on all have certain influence on the core shearing machine.

Collect

Description

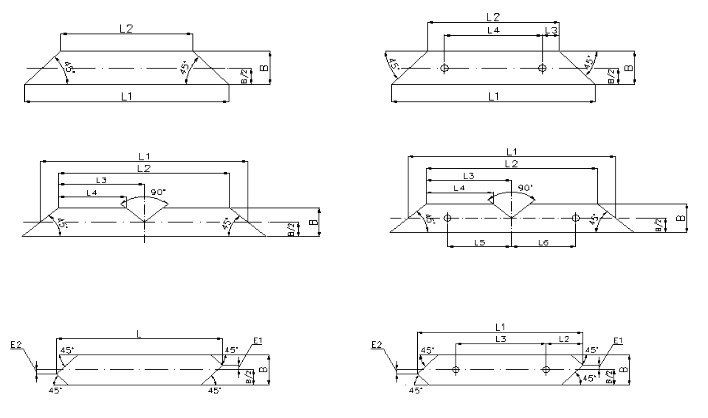

The transformer shear production line adopts multiple sets of AC servo system. Respectively used in: material transmission channel by servo motor to set material width in screen operation and automatic positioning. Shearing and v-notching adopt AC servo motor as driving power, with fast response speed, low noise, small vibration, convenience maintenance. Features Frequency speed decoiler, automatic tracking system. Electrical control double loading , Easy position Replacement. No need pit for Material Storage Device, Ensure safe and convenient. PLC Control, Servo adjust width, Servo feed V notching, Hole punching, Shearing device kinds of collocation, meet all kinds of needs Automatic depiler , stacking neatly Core type by transformer core lamination machine Two shear one punch Two shear two punch Two-shear Two-punch Central Positioning Stepping

Technical parameter

RFQ

Payment & Delivery Payment term : L/C,T/T,Western Union Delivery time : 90 working days after advance Guarantee: The guarantee period shall be 12 months counting from the date of signing the Acceptance Report of this machine at the end-user’s site,but no longer than 14 months from the date of delivery. What is YIBO? 8A Class Transformer Home with a full solution for the Transformer Industry 1, A real manufacturer with complete in-house facilities and passed ISO9001:2020 quality control system. 2, A professional R&D Center, having collaboration with well-know Shandong University. 3. A top performance company Certificated with International Standards like ISO, CE, SGS and BV etc. 4, A better cost-efficient supplier , all key components are international brands like Simens, Schneider and Mitsubishi etc. 5, A reliable business partner, served for CASC,CRRC,CASDY,ABB,DELIXI, EATON, RITZ,TENGEN, Russia Military Enterprise etc in past 23 years. 6. A factory has passed the global TOP 500 enterprise clients inspection. 7. A market share in China is over 85% and Top 3 in electrical equipment field. 8. A have mainly manufacture the whole of electrical equipment and technical output service for decades. Q1: How to grantee the quality ? The quality is approved by national certificate ,several senior inspection personnel ,the brand material supplier ensure the safety and reliability of everything from storage to finished the goods . Q2:Do you provide overseas installation and training ? A: It’s optional .Our company will provide the guidance and videos for installation and commissioning. If you need ,we can send engineers for for overseas installation and training. Q3:How long is the warranty ? A:The warranty period is 12 months .During Any problems ,our company will respond within 24 hours . |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||