|

|

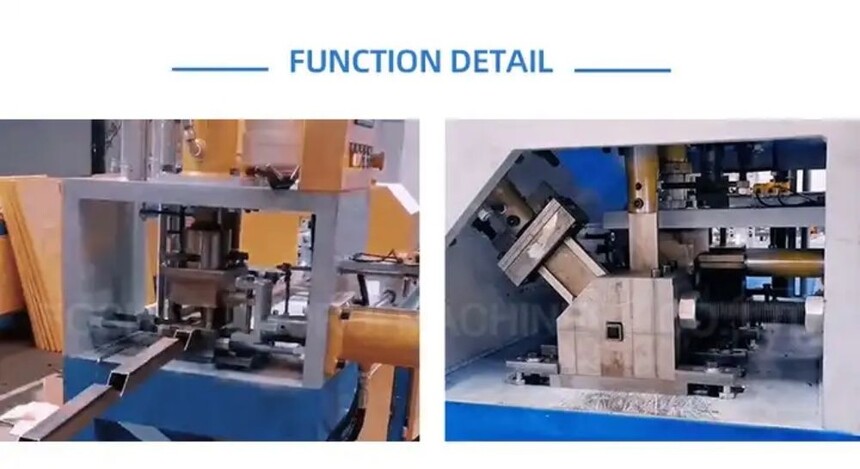

Integrated Semi-automatic angle punching machine servo feeding and manual loading material

Collect

Product Description

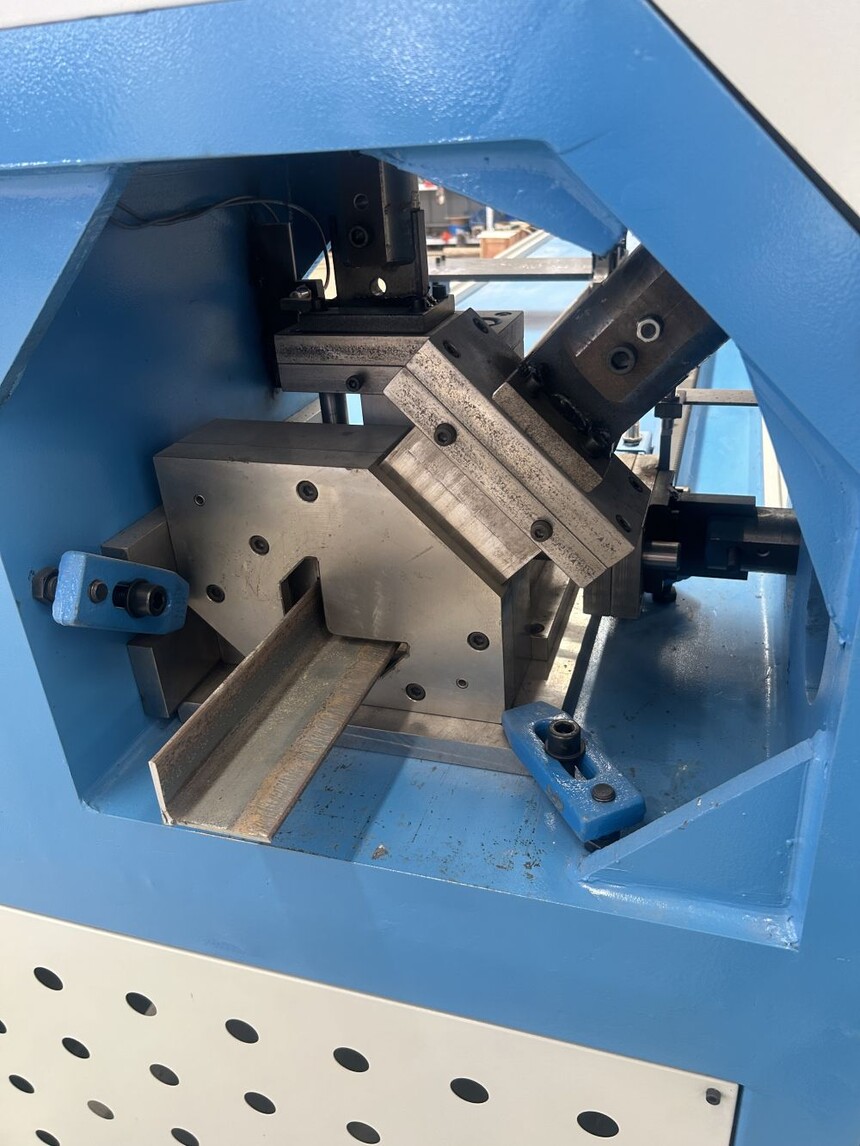

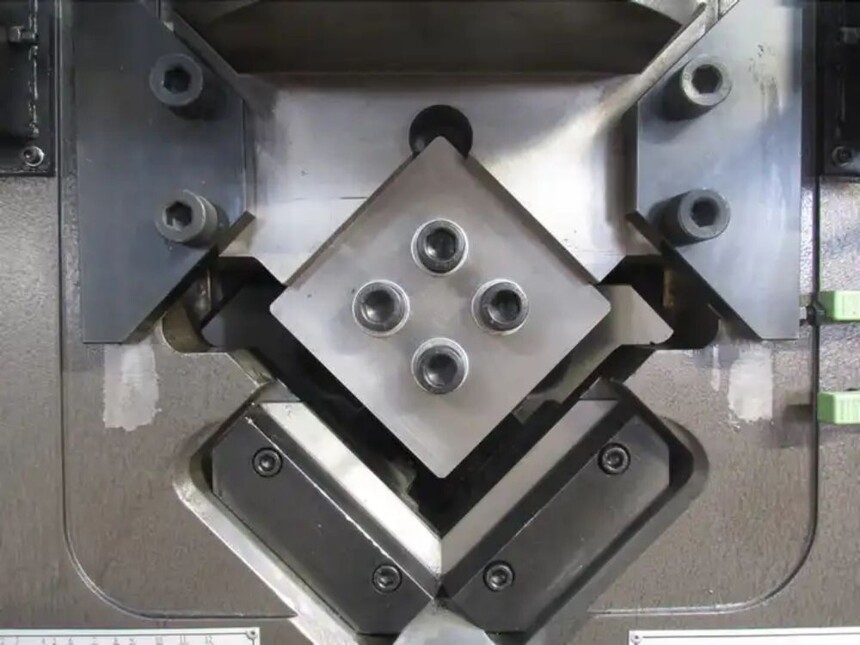

Make various hole types more accurate and efficient, and ultimately achieve the efficiency and precision required by customer process requirements. CNC punch machines have been widely used in the industry and are characterized by advanced technology, high punching accuracy, wide range of processes and high degree of automation. Works reliably and stably even under high intensity. During the automatic punching process, the metal pipe undergoes a series of precise positioning, and each pipe is precisely controlled through servo and PLC control to eliminate inconsistencies in hole patterns in different parts of the pipe and profile, thereby achieving high-precision punching. Compared with other stamping methods, the machine's control system has the functions of storing, calling, and editing process and equipment parameters, as well as misoperation identification and alarm. During operation, parameters such as pipe thickness and profile size can be set on the control panel. Angle Punching and Cutting Machine can be adjusted according to the existing parameters in the database or manually to achieve work punching and precise positioning. The control system of this machine adopts Taiwan Yaskawa PLC controller, and the speed is controlled by servo motor. All machine movements are centrally controlled from the control panel and feature a user-friendly touch screen interface. For operational safety, emergency stop switches are installed at four prominent locations on the machine. It is also equipped with a digital display to display the displacement value, making operation simple and fast. In just a few seconds, products can be punched with high precision and efficiency. CNC punching machine are the preferred punching equipment for vehicle manufacturing, elevator manufacturing, construction industry, scaffolding industry, furniture industry, fitness equipment, guardrail industry and other industries. Angle Punching Machine play a vital role in the stamping, appearance and accuracy of various industrial structural parts! Datas

|