|

|

CNC Busbar Punching Bending Cutting Shearing Machine Busbar Processing Machine

Collect

Description

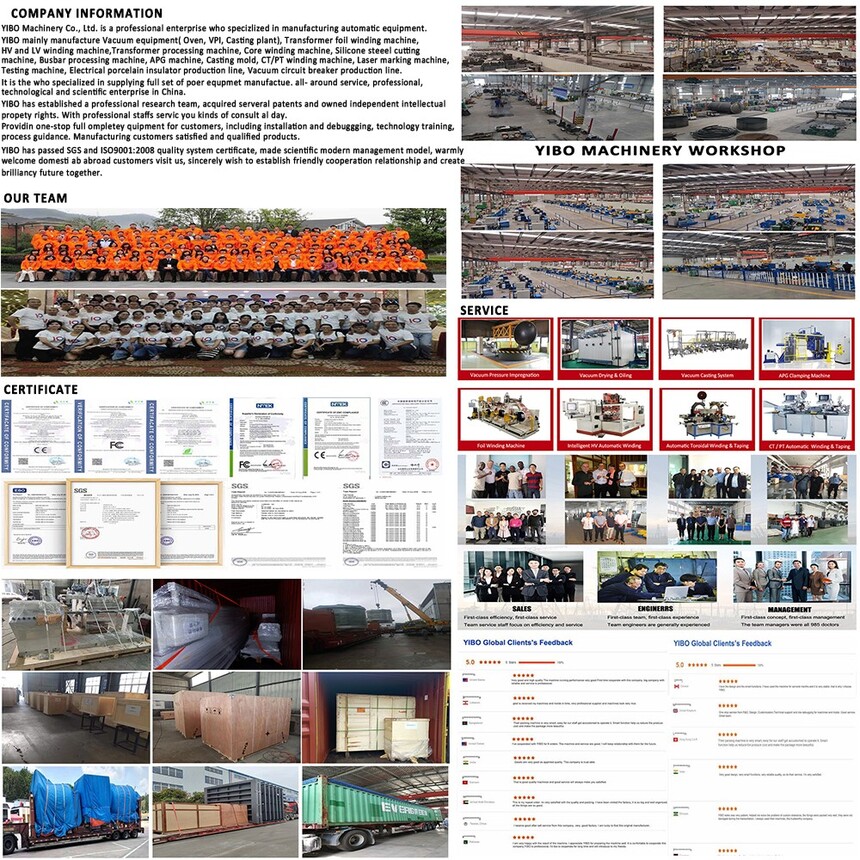

Our BUSBAR machine have three stations: Punching, Cutting and Bending. It can processed for copper and aluminum. Three stations can work at the same time so it will save your time and improve your work efficiency. YB802-6C CNC bus punching and cutting line adopts six axis control, servo clamp, is a kind of automatic feeding, automatic positioning, automatic clamping, automatic punching, automatic shift, automatic shearing, automatic embossing, automatic feeding and other perfect combination as one of the high degree of automation, accurate positioning, easy to use CNC equipment. Widely used in high and low voltage switchgear, transformer manufacturing, box-type substation, busbar slot and other industries, used in various specifications of copper, aluminum busbar automatic processing, with high degree of automation, processing speed, high precision advantages, is the ideal equipment for busbar processing. (Attached with equipment floor plan). Main technical data: 1. The main performance characteristics

|